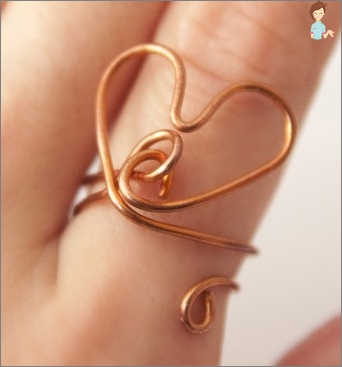

Wire Wrap Art: Making Beautiful Wire Rings with their own hands

Jewelry from the wire today again in fashion: learning how to make sophisticated decorations with your own hands, you will always look stylish and bright

How to create an original image and to avoid unnecessary expenses? Make a fashionable decoration yourself! Making cute things from the most ordinary wire – gaining popularity of needlework called Wire Wrap Art.

Even in the Middle Ages, the masters were out of the fine jewelry wire incredibly stylish and elegant decorations: the thinner and exquisite it looked like a finished product, the arterier was considered the master. Today we will tell you how to make a beautiful and at the same time an extremely simple ring made of copper or aluminum wire with your own hands. Having mastered the most primitive weaving, with time you can «fill» and go to the manufacture of complex elements. Just give the will of fantasy!

Step 1. Basis for rings

To begin with, it should be decided on the material that you plan to use in the work: The first weaving experience is recommended to acquire aluminum or steel. Such a metal is inexpensive, therefore it is considered an affordable consumator, which can be safely spent on all sorts of experiments.

To begin with, it should be decided on the material that you plan to use in the work: The first weaving experience is recommended to acquire aluminum or steel. Such a metal is inexpensive, therefore it is considered an affordable consumator, which can be safely spent on all sorts of experiments.

Simplest «basket» The type of weaving, which is devoted to this master class, allows for the use of two different materials.

So, aluminum can be used for the manufacture of a thick and massive base (in the course of work, do not forget that this is a rather fragile metal), and for an elegant braid – a thin wire from copper without coating (this is important!).

In the future, as the required skills are purchased, you can start making a copper wire rings – soft, obedient and at the same time strong. The more complicated the product, the more small parts in it – the thinner and more elastic should be the source material. Therefore, with the time of the master, one way or another, go to copper.

So, to make a pretty ring from the wire with your own hands, you will need:

- 2 MOCA Wire of different thickness (0.03 for winding, 0.1 for the manufacture of frame);

- beads or semi-precious stones for decor;

- Rigel for winding the base (you can use a regular marker or a thick marker without faces);

- Floors and Kruglogs.

So, let’s start our master class and try to make the basis of the product:

I cut off with nipples from aluminum or copper slices a piece of the desired length (depending on the number of turns that the ring should cover the finger, and the thickness of the thumb);

I cut off with nipples from aluminum or copper slices a piece of the desired length (depending on the number of turns that the ring should cover the finger, and the thickness of the thumb);- Then carefully make the round rolls of a little loop at every end of the segment. It is necessary that the rings made the edges made with their own hands did not injure the skin.

- Next, we make several turns on the size of the finger using a felt-tip or a brigal. Usually two turns are enough: if you make the base of the ring too thick, it will look rude, and it is much more complicated to overwrite the three-four lines of the base.

- To a wicker ring from wire (aluminum, copper or steel) looked symmetrically, the loops should be located on one line – opposite each other. The distance between the turns should not be too large, but it should not be closely customized, because it complicates the process of the winding (the next stage of transformation of metal pieces into a fashionable piece). A para-triple of millimeters is the optimal distance that allows you to freely operate with a thin wire for the winding and does not turn the product into a rough wide «Naika».

Step 2. We make a winding of a thin wire rings

To make a winding, we take the end of a thin copper wire and make 5-7 dense turns at the base of the looping (bodies can not be used, it is easier to gradually releasing the desired amount of material from a whole month).

Then we tighten the first turns of the braid as much as possible and begin to swell the two parallel running lines of the base. You need to fen the end of a thin wire alternately for each of the two main turns, so that elegant and tight weaving.

And so that the drawing lay smoothly and neatly, without bandage, constantly keep a thin wire under the tension.

And so that the drawing lay smoothly and neatly, without bandage, constantly keep a thin wire under the tension.

This is the easiest type of braid: if you are easily mastered, and options «for beginners» It seems to you too simple, it is worth visiting the master class on learning more complex types of weaving – for example, imitation of a knitted canvas, a figure chain, work with flat elements and T.D. With the help of submitted means, you can create real masterpieces, especially if you use original materials – unworn stones, shells, artificial or natural pearls. Unusually and spectacularly look at wooden inserts, braided openwork wire «Frames».

Step 3. How to make for rings from wire decor?

Now you know how the ring of the simplest type is woven from the wire. But the master class has not yet been completed: the time to decorate the decoration of semi-precious stones made by their own hands or glass beads to make it really original.

To do this, we choose a small (on the width of the ring) bead or drilled in the center of the pebble, and then skip the thin wire through the hole. To make this manipulation easier, choose beads with wide and smooth holes.

Then we introduce the ends of the wire segment with the bead between the braid twists, we primar them to the upper and lower cages of the base, fix the bead and carefully cut up too much. Actually, this end the main part of the master class «Wire ring with their own hands».

Tricks used in the manufacture of rings with their own hands

Completing the introductory master class, it is worth mentioning small tricks that will help make

Completing the introductory master class, it is worth mentioning small tricks that will help make

The process of creating wire jewelry with your own hands less troublesome and time consuming.

If in the process of multiple bends and tightening thin copper wires become less elastic, you can slightly warm them over the gas burner – they will instantly acquire the former flexibility.

And to make the finished product glitter, slightly polish it with the help of ammonia: the jewelry will immediately acquire a noble view.

As you can see, learn such art for everyone, so dare, and let your fingers decorate rings of our own production!