Pyrolytic cleaning oven: how to clean the oven quickly and effortlessly?

Each hostess is familiar with the problem of cleaning ovens and frying cabinets from dirt and fat. How to cope with this problem and prevent her appearance? Pyrolytic purification systems will help

No matter how trying to carefully and carefully operate the oven and wipe it after each use, on its inner surface, inevitably forms a layer of burnt fat and dirt. So it turns out that you eat a homely baked chicken or meat love almost everything, while washing after the preparation of these dishes a certain oven!

And it is not surprising, because the work is a dirty, taking a lot of time and forces. In addition, the burnt fat is very difficult to launder without damaging the surface. Wanting to ease the work of horses, caring developers of household appliances seriously puzzled the problem of cleaning the inner walls of ovens.

And it is not surprising, because the work is a dirty, taking a lot of time and forces. In addition, the burnt fat is very difficult to launder without damaging the surface. Wanting to ease the work of horses, caring developers of household appliances seriously puzzled the problem of cleaning the inner walls of ovens.

The result of their works was the invention of the pyrolytic cleaning system of the oven. What it is and than such cleaning differs from catalytic and hydrolytic cleaning?

What is pyrolytic surface purification?

The meaning of this technology is concluded in its name. Pyrolysis (Pyr – heat and Lysis – decomposition, decay) – this is a process of burning out of fat and other contaminants at high temperatures.

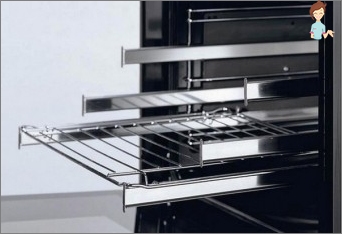

This method of cleansing is very simple and convenient, everything you need to make the hostess is to free the stove from the lattices and dishes, which is not able to survive heating to such high temperatures (500 ? C) and turn on cleaning. Be sure to remove telescopic guides along with fasteners, if any.

Pyrolytic cleaning ovens allows you to quickly and without damaging the surface, remove fat and dirt, which under the influence of high temperatures are simply turning into ashes. After the cleaning cycle is completed, the ashes of the burnt pollution is removed using a wet sponge, additional use of any abrasive or detergents is required.

Security measures

Wind cabinets in which the manufacturer provides a pyrolytic cleaning function, are made of special high quality materials.

In addition, for working with such a temperature regime, oven developers with such a cleaning system have provided a number of security measures to which in addition to heat-resistant and high-strength material include:

good and reliable thermal insulation, preventing heating around the overall cabinet of objects;

good and reliable thermal insulation, preventing heating around the overall cabinet of objects;- Additional cooling system;

- In the oven door, thick tempered glasses are installed (usually 3 pcs.);

- During pyrolytic cleaning, the door is blocked as soon as the temperature inside it reaches 300 ° C, and when cooled to 200 ° C, the lock is automatically removed. This prevents accidental opening and receiving burns;

- All models of brass and frying cabinets with a pyrolytic method of cleansing are equipped with a filtration and ventilation system that prevent to entering poisonous compounds – combustion products (soot and smoke), room.

The duration of cleaning the oven depends on how much it is contaminated. On average, the duration of such purification is 1.5-3.0 hours, while most of this time is spent on the heating of the oven and on its subsequent cooling.

Some models of wind cabinets equipped with a pyrolytic cleaning system are complemented by special catalysts that fix the degree of contamination, which helps to set the optimal duration of cleaning.

Other ways of cleaning

Due to the fact that embedded ovens with pyrolytic cleaning are not cheaps because of the high degree of protection and availability of various additional systems, many manufacturers also produce oven with a catalytic cleaning system. This method is most common, it is used in the ovens of such firms as Kaiser, Ariston and DR.

The essence of the method is to use the special enamel of high porosity, due to which fat is absorbed. During the operation of the oven temperature of 200 ° C and higher, the absorbed fat is split into water and soot, so the cleaning of the oven is constantly.

A significant disadvantage of such a method is the low degree of cleaning compared to pyrolytic. Such enamel can also be washed with the usual not abrasive means.

Another way to get rid of the air fat is a hydrolytic purification based on the principles of the hot steam, which contributes to the softening of dirt and fat. After such a cleaning, pollution is easily removed using a conventional cloth.

In addition, a special enamel is used in the ovens with a hydrolytic cleaning system, which does not allow dirt to penetrate deep into the surface of the oven.

What kind of oven cleaning system is more efficient catalytic or pyrolytic? To give an unequivocal answer is quite difficult, that it all depends on many factors. Of course, it is much easier to launch pyrolytic cleaning every two weeks and after easy to remove the ash with a damp cloth.

What kind of oven cleaning system is more efficient catalytic or pyrolytic? To give an unequivocal answer is quite difficult, that it all depends on many factors. Of course, it is much easier to launch pyrolytic cleaning every two weeks and after easy to remove the ash with a damp cloth.

However, if you are preparing often and gradually and after each cooking, do not be lazy to wipe the oven, it is quite suitable for your device with a catalytic cleaning system, T.To. Clean minor contamination remaining after wiping, it is possible for one cycle cooking.

Choose the most convenient way for you and enjoy fast and convenient cleaning!